Table of Contents

Introduction to Digital Twins for Fleet

In the ever-evolving world of maritime logistics, digital transformation is no longer just a buzzword—it's a necessity. One of the most innovative technologies reshaping the industry today is the concept of digital twins. These virtual replicas of physical assets, processes, or systems are unlocking new opportunities for fleet and port optimization, aiding maritime businesses in streamlining operations, reducing costs, and enhancing decision-making in real-time.

This comprehensive guide from Dbiz.ai will explore how digital twins are revolutionizing port and fleet management, their core components, and the real-world benefits they contribute to the global supply chain. Partnerships with visionary companies like DBiz.ai have proven invaluable as businesses strive to harness the power of digital twins. DBiz.ai specializes in offering advanced solutions tailored to the unique requirements of maritime logistics. By integrating expertise in AI-driven analytics and IoT systems, DBiz.ai enables shipping companies and port operators to fully realize the transformative potential of digital twin technology, delivering smarter, more efficient operations and fostering industry growth in an increasingly competitive and dynamic environment.

What Are Digital Twins?

Digital twins are virtual representations of physical assets, processes, or systems, designed to replicate their real-world counterparts in every detail. These digital models are powered by data and advanced technologies such as AI and IoT, enabling real-time monitoring, simulation, and analysis. By creating a dynamic and interactive digital framework, digital twins help businesses predict outcomes, optimize operations, and make informed decisions with precision. In maritime logistics, digital twins are revolutionizing fleet and port management, offering unprecedented opportunities to streamline processes, reduce costs, and enhance productivity in an ever-changing global environment. This transformative technology paves the way for smarter, more efficient maritime operations.

Core Components of a Digital Twin System

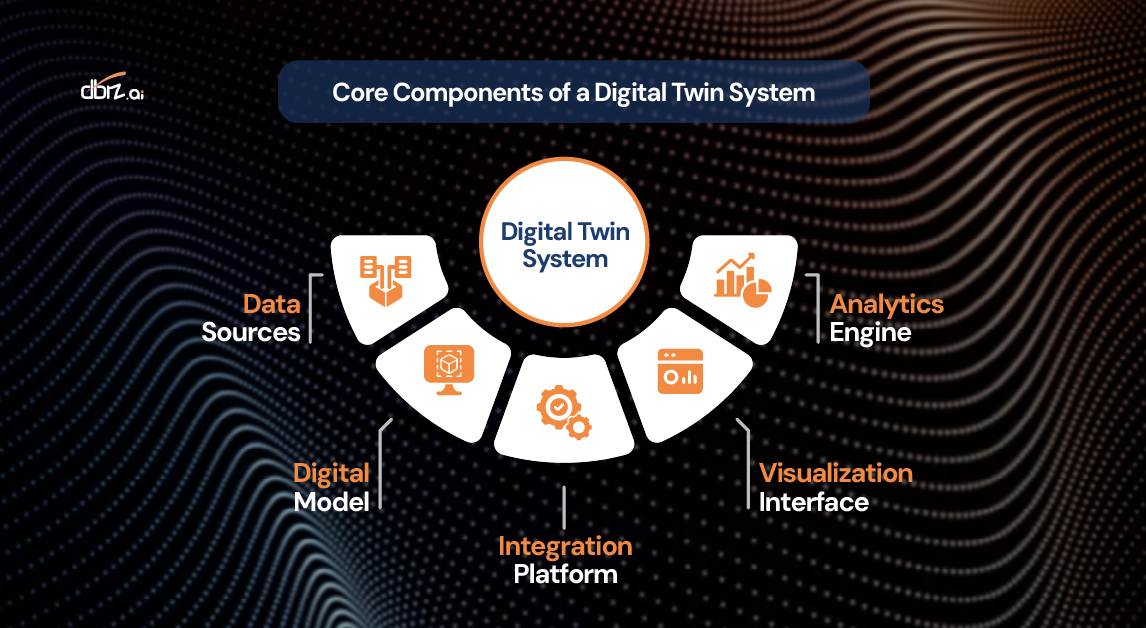

Understanding the functionality of digital twins involves breaking down their components:

Data Sources:

Real-time inputs from IoT sensors, GPS trackers, weather data, and historical analytics.

Digital Model:

A dynamic simulation built on AI and machine learning that mirrors the real system.

Integration Platfrom:

Connects disparate systems and ensures seamless data flow.

Visualization Interface:

Dashboards or AR/VR interfaces that allow operators to interact with the digital twin.

Analytics Engine:

Provides insights, predictions, and recommendations for optimization.

DBiz.ai offers all these components in a cohesive platform tailored for maritime logistics, ensuring seamless integration and optimized performance.

Fleet Optimization Using Digital Twins

Fleet management is one of the most resource-intensive aspects of maritime logistics. Digital twins can significantly improve the deployment, maintenance, and monitoring of ships:

Real-Time Vessel Tracking:

With GPS and satellite data, digital twins offer instantaneous visibility into each ship’s location, status, and estimated time of arrival. This enables more accurate scheduling and reduces idle time at sea or at port.

Predictive Maintenance:

By monitoring engine performance, fuel usage, and mechanical wear, digital twins help forecast potential failures before they occur. This reduces unplanned downtime and ensures vessels stay operational longer.

Fuel Efficiency:

Optimizing routes and engine settings based on weather conditions and sea currents can lead to significant fuel savings—both financially and environmentally.

Crew Performance and Safety:

Digital twins can also analyze crew behaviour and working conditions to enhance onboard safety protocols and improve overall crew well-being.

Port Optimization with Digital Twins

Ports are complex ecosystems requiring constant coordination. From container handling to traffic flow, digital twins can transform port operations in several ways:

Port Layout Simulation:

Using digital twins, port authorities can simulate various infrastructure scenarios before committing to expensive upgrades. This ensures optimal layout and maximizes throughout.

Traffic Flow and Congestion Management:

By analyzing real-time data on ship arrivals, truck movements, and loading/unloading times, ports can reduce congestion and bottlenecks, improving overall efficiency.

Equipment Monitoring:

Cranes, gantries, and other port equipment are expensive assets. Digital twins enable predictive maintenance and help prevent costly breakdowns.

Environmental Compliance:

Ports face increasing pressure to reduce emissions and noise pollution. Digital twins allow operators to track environmental impact and ensure compliance with green port initiatives.

DBiz.ai helps ports achieve these optimizations by providing tailored digital twin solutions that seamlessly integrate with existing port systems.

Benefits of Implementing Digital Twins in Maritime Logistics

Enhanced Decision-Making:

Digital twins provide data-backed insights that support strategic decisions, from route planning to infrastructure investments.

Cost Reduction:

By identifying inefficiencies, predicting failures, and improving resource allocation, digital twins help cut operational costs significantly.

Greater Sustainability:

Optimized fuel usage, reduced waste, and improved emissions monitoring contribute to a more eco-friendly supply chain.

Improved Stakeholder Communication:

Visual interfaces and dashboards enable clear communication among all stakeholders—from port authorities and shipping companies to logistics providers.

DBiz.ai leverages its expertise to maximize these benefits, ensuring clients achieve their operational goals.

Future Trends in Digital Twin Technology

As technology continues to evolve, so too will the capabilities of digital twins. Key emerging trends include:

- AI-Driven Automation: Autonomous decision-making based on predictive models.

- AR/VR Integration: Immersive digital twin environments for training and simulations.

- Blockchain Integration: Secured and transparent data sharing across the maritime supply chain.

- Edge Computing: Real-time processing of data closer to the source for faster insights.

DBiz.ai stays at the forefront of these innovations, continually refining their offerings to incorporate the latest advancements.

How to Get Started with Digital Twins

If considering implementing digital twin technology for your fleet or port operations, follow these steps:

- Assess Current Systems: Evaluate the existing infrastructure and identify data gaps.

- Define Objectives: Clearly outline goals—cost reduction, improved safety, sustainability, etc.

- Choose the Right Platform: Select scalable solutions compatible with existing systems.

- Start Small: Begin with a pilot project focused on one vessel or port function.

- Scale Strategically: Use learnings from the pilot to expand implementation across the fleet or port.

DBiz.ai can assist throughout this process, from initial assessment to full-scale implementation, ensuring a smooth transition to digital twin technology.

Conclusion:

Digital twins represent a transformative force in the maritime industry. By bridging the physical and digital worlds, these technologies empower operators to optimize fleet performance, streamline port operations, and future-proof logistics strategies. Whether managing a fleet of cargo vessels or overseeing one of the world’s busiest ports, embracing digital twin technology is crucial for staying competitive in an increasingly complex global market. Now is the time to harness the full potential of digital twins—not merely to survive, but to thrive in the future of maritime logistics.

Frequently Asked Questions

How do digital twins help in fleet management?

Digital twins help fleet managers by providing real-time tracking, enabling predictive maintenance, optimizing fuel usage, and improving route planning. These benefits lead to lower operational costs, fewer delays, and better safety for crew and cargo.

Can digital twins improve port efficiency?

Yes. Digital twins enhance port operations by simulating port layouts, reducing congestion, improving equipment maintenance, and supporting environmental compliance. They enable port authorities to make faster, more informed decisions that boost overall throughput.

What data is needed to create a digital twin?

Creating a digital twin typically requires data from IoT sensors, GPS systems, weather forecasts, historical logs, maintenance records, and real-time operational data. This data is used to mirror the behavior of physical assets and optimize performance.

Are digital twins expensive to implement?

Initial implementation can involve a high upfront cost, especially for infrastructure upgrades and system integration. However, the long-term ROI is significant due to operational savings, improved asset lifespan, and increased efficiency.

What is the future of digital twins in maritime logistics?

The future of digital twins in maritime logistics includes AI-driven automation, AR/VR integration, blockchain-enabled transparency, and edge computing for faster real-time analytics. As the technology matures, it will become a standard part of global shipping and port operations.

Explore other articles:

AI-Powered Supply Chain Optimization

Leverages AI to streamline operations, reduce costs, and improve supply chain efficiency.

AI-Driven Customer & Partner Portals

Personalized, intelligent portals enhancing engagement, collaboration, and efficiency with customers and partners.

Supply Chain Visibility & Transparency Solutions

Enhances real-time tracking, data sharing, and insights across the entire supply chain.